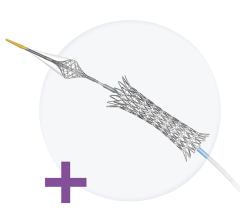

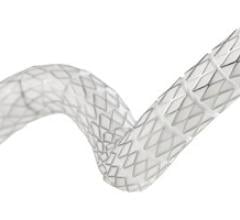

This bioabsorbable stent with 80 micron struts and 3.5 mm diameter was machined with Raydiance Smart Light, the world's only commercial grade ultrafast laser platform.

October 21, 2009 – Raydiance Corp., developer of the world’s first commercial-grade ultrafast laser, said today it made a major breakthrough in manufacturing a wide variety of bioabsorbable materials with precise, micron-resolution feature sizes and with no heat affected zones (HAZ).

Raydiance has been deploying its Smart Light MD platform with leading medical device companies to manufacture a range of bioabsorbable vascular stent designs and materials, as well as other biocompatible polymers.

The recent Raydiance work was performed on bioabsorbable materials such as polylactic acid, polyglycolic acid, and a variety of copolymers. The vascular stents machined by Raydiance had strut dimensions of 80 microns and less.

“The medical device industry has embarked on an exciting wave of innovation in small, extremely precise implantable devices,” said Scott Davison, president of Raydiance. “These new products and applications require a new tool that enables the machining of very small features without introducing heat to the process. Raydiance Smart Light is that tool.”

Raydiance will discuss this advance at the Medical Design and Manufacturing show in Minneapolis today and tomorrow.

For more information: www.raydiance-inc.com

November 24, 2025

November 24, 2025